In today’s fast-paced manufacturing environment, agility and efficiency are essential. Power Apps provides a low-code platform that allows manufacturers to quickly build custom applications to streamline operations—from inventory tracking and compliance to workforce and asset management.

In this blog, we explore 5 key examples of Power Apps in the manufacturing sector that are delivering real value.

What is Power Apps?

Microsoft Power Apps is a low-code development platform that allows organisations to quickly build custom applications tailored to their specific needs.

In the manufacturing sector, it helps digitise manual processes, improve data accuracy, and streamline operations—enhancing everything from inventory management to compliance and workforce tracking. Its flexibility and seamless integration with Microsoft tools make it ideal for driving efficiency and innovation on the factory floor.

5 Examples of Power Apps in Manufacturing

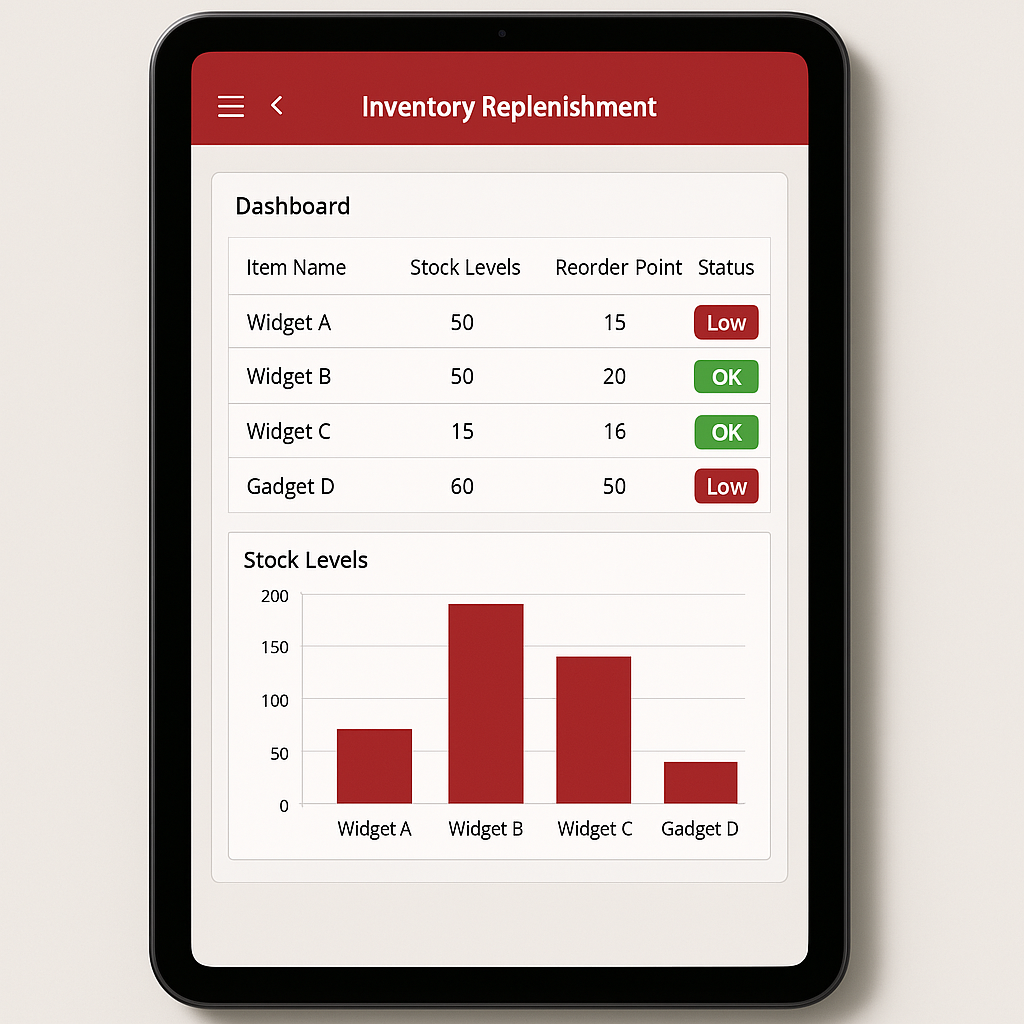

Inventory management – Enable real-time inventory tracking

Power Apps can help enable the development of applications that provide real-time inventory tracking, automate stock replenishment and integrate with barcode scanning systems. These solutions reduce manual errors, optimise storage space and enhance order accuracy.

For instance, by integrating Power Apps with IoT devices and ERP systems you can monitor warehouse conditions, ensuring optimal storage environments for sensitive materials. Integrations like this can lead to proactive maintenance and reduced downtime.

At Bridgeall, we’ve supported manufacturers in transforming their warehouse operations through Power Apps. An example use case would be with our clients Whyte & Mackay, where we developed a bespoke warehousing and maturation tracking solution. This custom Power App provided end-to-end visibility across their cask inventory, improving traceability and supporting better decision-making across the business.

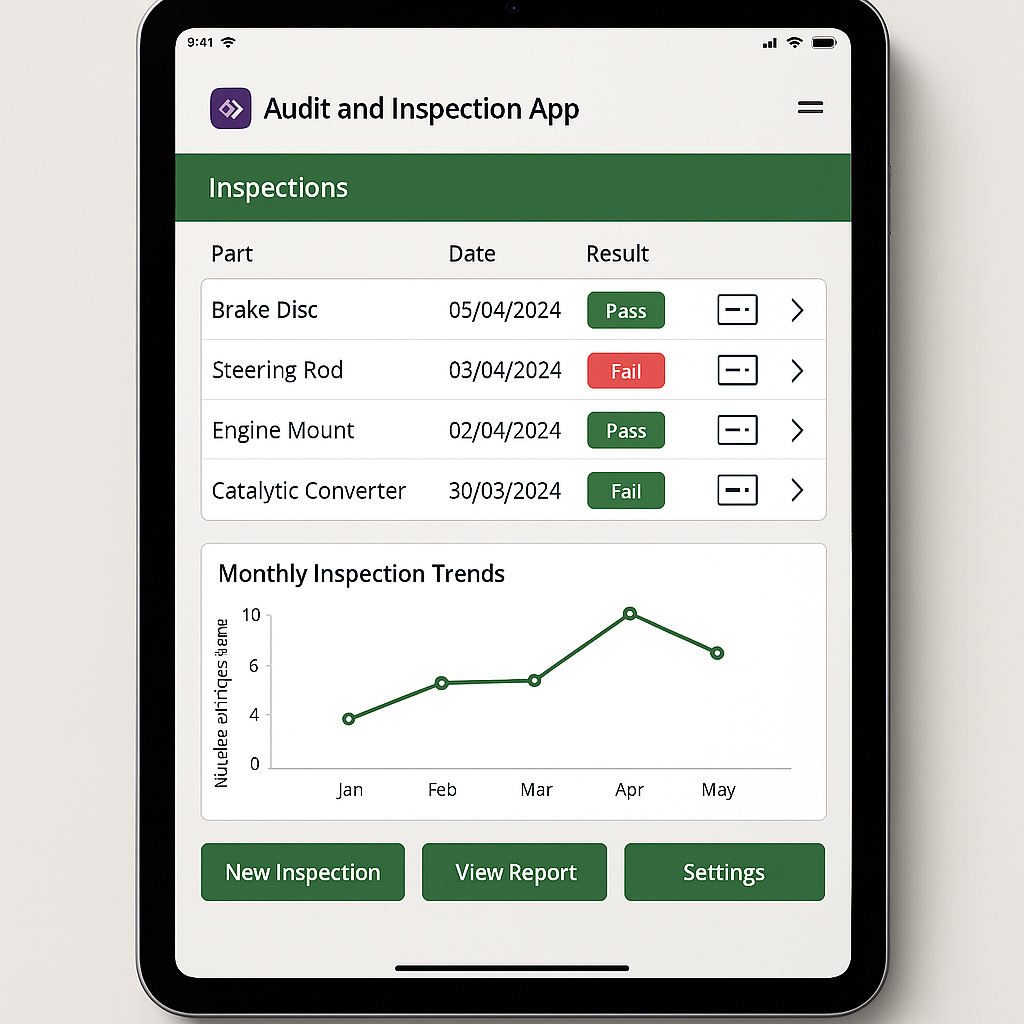

Audit and inspection app – Digitise quality checks

Manufacturers face strict compliance requirements around product quality, safety, and environmental standards—often documented through extensive inspections and reports.

Power Apps can significantly reduce this burden by replacing paper checklists and forms with a custom inspection management app. These apps can include standardised audit templates, support custom questionnaires, and validate data in real time—minimising errors and ensuring completeness.

Integration with tools like Power BI and Dynamics 365 allows manufacturers to automate follow-up actions, manage parts inventory, and schedule maintenance. For example, if a maintenance issue is flagged, the app can automatically trigger part ordering and assign a technician.

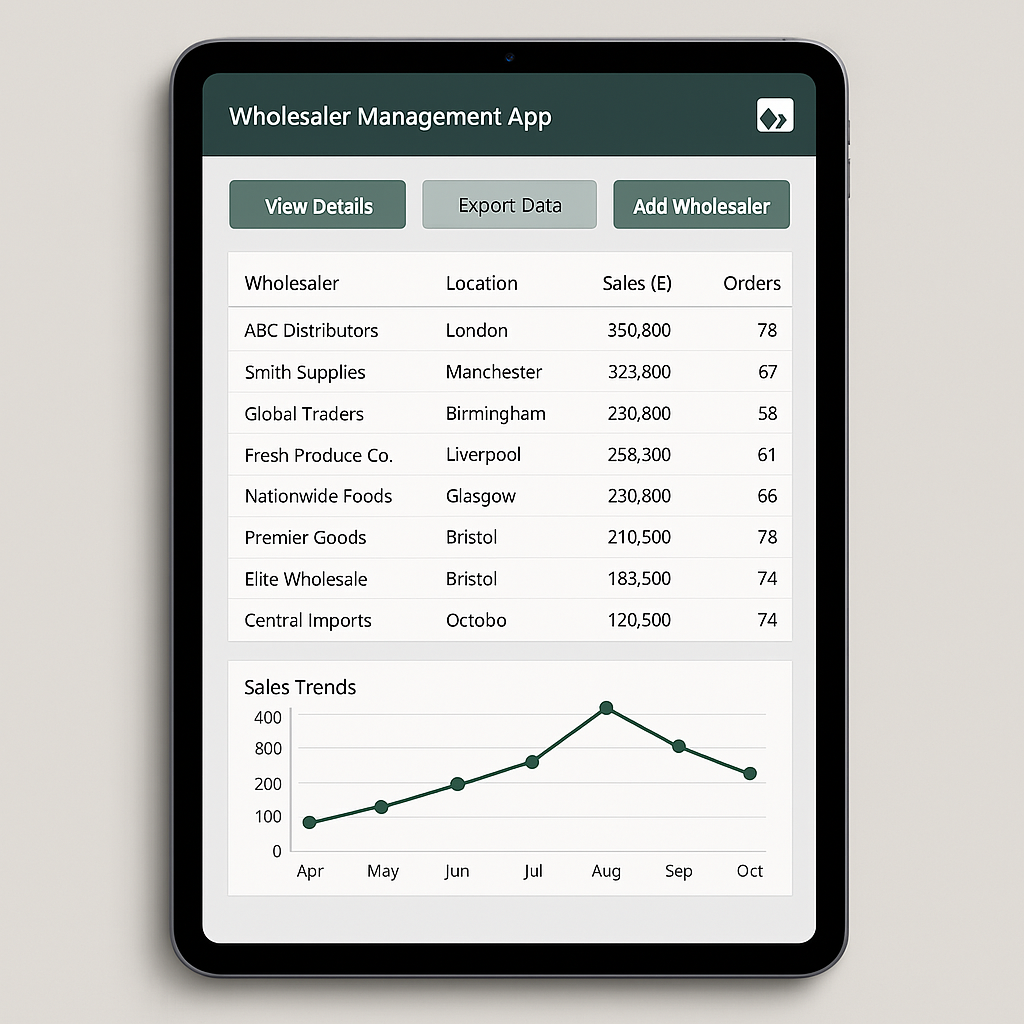

Wholesaler management – Centralise wholesaler information

Managing relationships with wholesalers is vital for distribution efficiency. Power Apps can centralise wholesaler information, track orders, and monitor performance metrics. This centralised approach ensures consistent communication, timely deliveries, and data-driven decision-making.

Custom dashboards can also provide insights into sales trends, helping manufacturers and wholesalers align strategies and forecast demand more accurately.

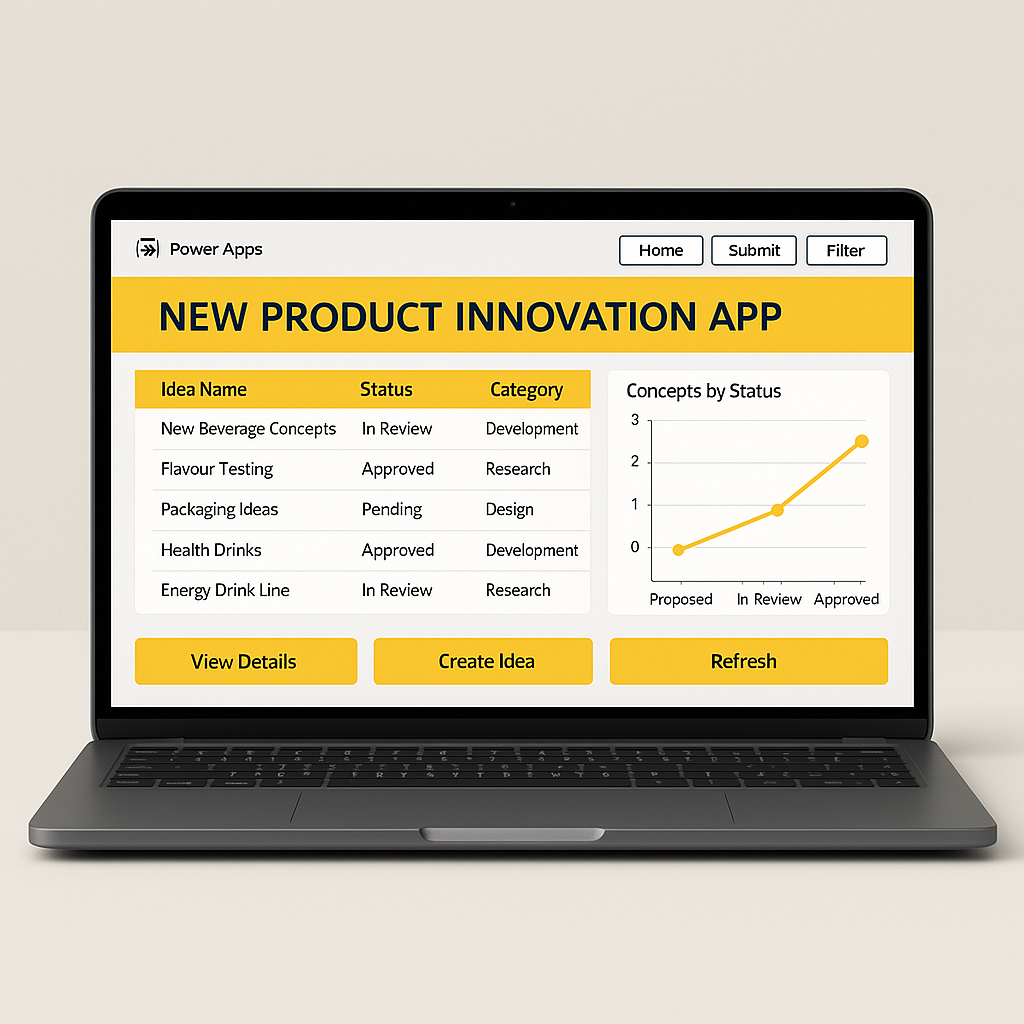

New product innovation – Provide greater visibility across the new product stage

Bringing new products to market requires seamless collaboration across departments. Power Apps facilitates this by providing platforms where teams can share ideas, track development stages, and manage approvals. Custom applications can also integrate customer feedback directly into the development process, ensuring products meet market demands.

By leveraging Power Apps, manufacturers can reduce time-to-market and foster a culture of continuous innovation.

We helped our clients Whyte & Mackay modernise their approach to innovation. We delivered a tailored Power App that streamlined their product development lifecycle, improved cross-functional collaboration, and provided greater visibility across every stage—from concept to launch.

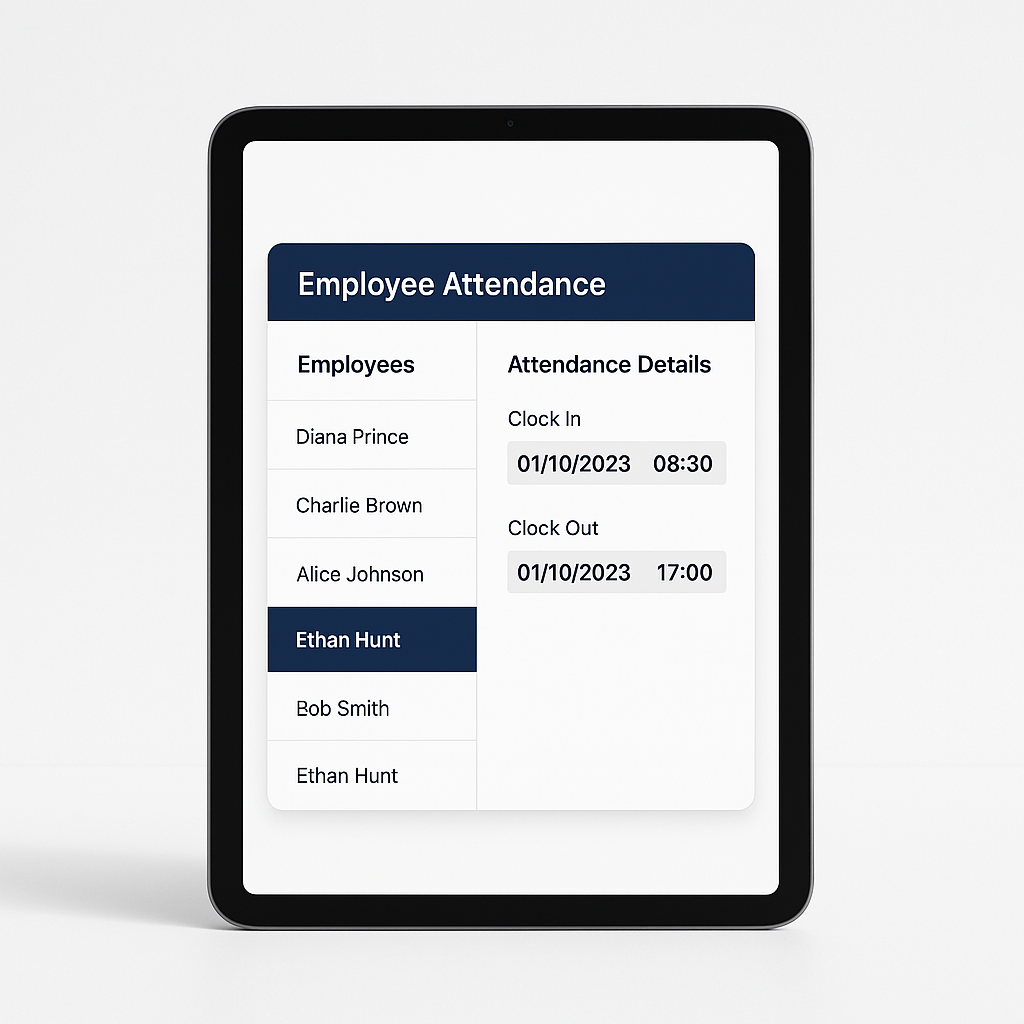

Employee attendance tracking app – Track employee clock-in/out and shift changes

Accurate time tracking on the production floor is essential for both operational efficiency and compliance. However, it is quite common for frontline workers to get side tracked and forget to clock in or out leading to gaps in workforce analytics. Manually tracking these inconsistencies could build up to be quite the task which is where Power Apps can help.

By developing a tailored time management solution with Power Apps, organisations can monitor shift hours, track time spent on specific assembly lines, and log usage of key equipment. When integrated with the facility’s access control systems, attendance data can be captured automatically as employees enter and exit the premises.

You can also take this a step further by using Power Automate to consolidate attendance logs into digital timesheets and send them directly to HR for processing.

At Bridgeall we’ve worked with several manufacturing clients to help them use Power Apps and address their unique business challenges. You can learn more about these projects here.

If you’re interested in developing custom Power Apps solutions for your manufacturing operations, you can contact our team here. Our expertise ensures that your applications are tailored to meet your specific needs, driving efficiency and innovation across your organisation.